Offshore Marine Aquaculture

Situation

Intensive aquaculture increased dramatically in the past decades. Fjords, Shelfs and protected coastal waters are highly polluted and loaded by sea lices.

Finding Solutions

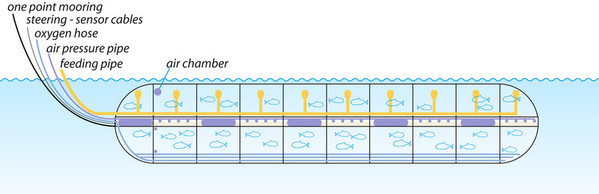

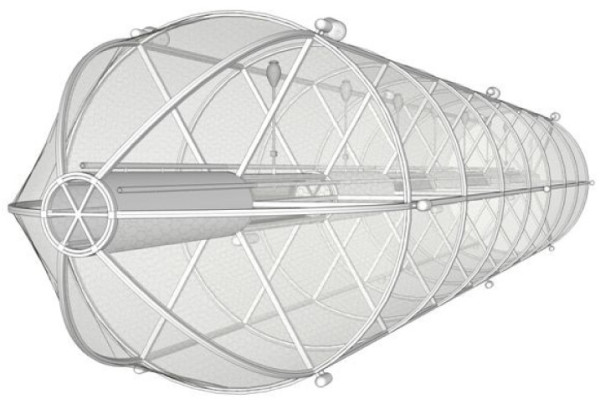

"Beck - Autonomous Marine Fish Farm" is an one point anchored, cylindrical, free floating, submerging and revolving fish cage with its static strength in the axial pipe and not in the peripheral frame as all conventional cages.

This unique design save a lot of cage structure material, is low cost, sustainable, economic and profitable.

Some Countries anounce of having semi submerging offshore fish farms. But this farms, planned or realized, cost over 1.000 EURO/m³ cage volume.

The amortization period is over 15 years, not conidering interest and other costs.

The repayment of investments of Beck - Marine Fish Farm is less than 1 1/4 year.

The patented innovation – Beck-Fish-Cage

1 or 3 cages are linked to a mobile, one point anchored Service Station (seagoing vessel) for 500 to 3.375 tons of fish, due to size of cages.

Alternatively: 6 - 12 cages linked to a moored Feeding Barge for 6.750 to 13.500 tons of fish.

Beck - Autonomous Marine Fish Farm

Concept

- The Fish Cage has a static strength for 10m waves heights and

submerge below waves trough into the natural environment of

fish for fishwelfare and sustainability.

- Fixed and flexible air chambers in the axial pipe let sink the cage to

a pre-given depth and lift it half out of water, calculated according

to the Principles of Archimedes.

- The cage never sink deeper and get not lost.

- When the cage is half out of water, the nets are cleaned by sun and air. - Nets never have to be changed.

- 1 or 3 cages are connected to a separate, seagoing Service Station.

Feeding hose, air-pressure pipe and cabel for digital functions are the

connection between both units.

- Alternatively: 6 to 12 cages are linked to a moored Feeding- and

Service Barge. Feeding, cage lifting, revolving and, dead fish

collecton takes place by the same equipment and facilities as at

the Mobile, Beck - Autonomous Marine Fish Farm.

R & D and Prototype Test

- The R&D was made in the Atlantic of Scotland and the static by the

University of Glasgow, included a Prototype Test of over 4 years with

a cage of L 20m x D 3m, linked to a 14 m fish-cutter with all service-

equipment.

- This one point anchored pilot fish farm circulated over a large area

and did not compile fish manure below the cage. There were no sea

lice and diseases over the test period of 4 years with Cod-Fish.

During 4 years 180 tons of Code-Fish were produced.

Fish Farm and Size of Cages

- The mobile, autonomous Beck - Marine Fish Farm has a dragon sail

and a hatchery and a battery of 40 - 50 KW, loaded by wind-solar,

large feed stores, automatic pellet feeder, management and research

facilities.

- Air chambers around the cage revolve the cage to any position for net

cleaning, harvesting, grading and automatic dead fish collection

- The remote control assure an autonomus ocean fish farming from

home office

- The standard cage of L 100 m x D 16 m has a volume of 20.000 m³

and produce about 500 tons fish.

- The Cage of L 100 m x D 20 m of 31.000 m³ produce 775 tons of fish.

- The Cage of L 100 m x D 24 m of 45.000 m³ produce 1.125 tons of fish.

- 3 cages can be fixed to a mobile sevice station.

- The Service Station can be a modified, second hand cargo vessel.